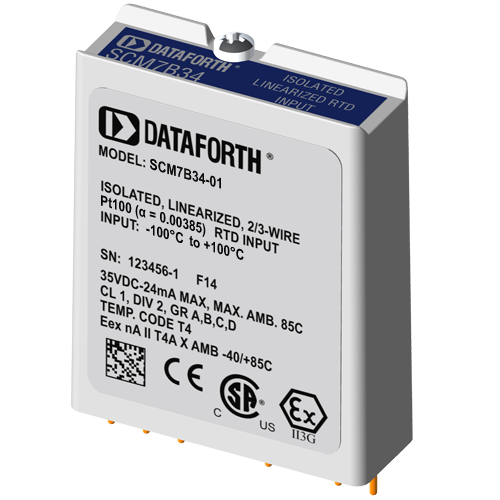

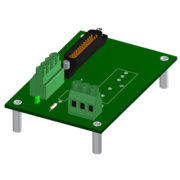

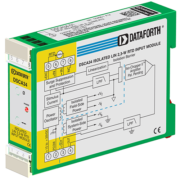

Each SCM7B34/34N RTD input module accepts a single channel of 100 ohm Platinum (a = 0.00385) or 120 ohm Nickel (a = 0.00672) RTD input and produces an input voltage in response to a low-level current excitation. The input signal is filtered, isolated, amplified, linearized, and converted to a high-level analog voltage for output to the process control system.

These modules incorporate a five-pole filtering approach to maximize both time and frequency response by taking advantage of both Thomson (Bessel) and Butterworth characteristics. One pole of the filter is on the field side of the isolation barrier; four are on the process control system side.

In response to the low-level current excitation signal, the RTD input signal is chopped by a proprietary chopper circuit and transferred across the transformer isolation barrier, suppressing transmission of common mode spikes and surges. The signal is then reconstructed and filtered for process control system output.

Linearization is achieved by creating a non-linear transfer function through the module itself. This non-linear transfer function is configured at the factory and is designed to be equal and opposite to the specific RTD non-linearity. Lead compensation is achieved by matching two current paths thus cancelling the effects of lead resistance.

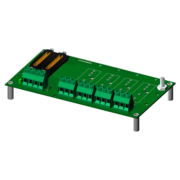

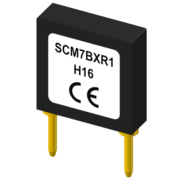

Modules accept a wide 14 – 35VDC power supply range (+24VDC nominal). Their compact packages (2.13″x1.705″x0.605″ max) save space and are ideal for high channel density applications. They are designed for easy DIN rail mounting using any of the “-DIN” backpanels.

re ideal for high channel density applications. They are designed for easy DIN rail mounting using any of the “-DIN” backpanels.